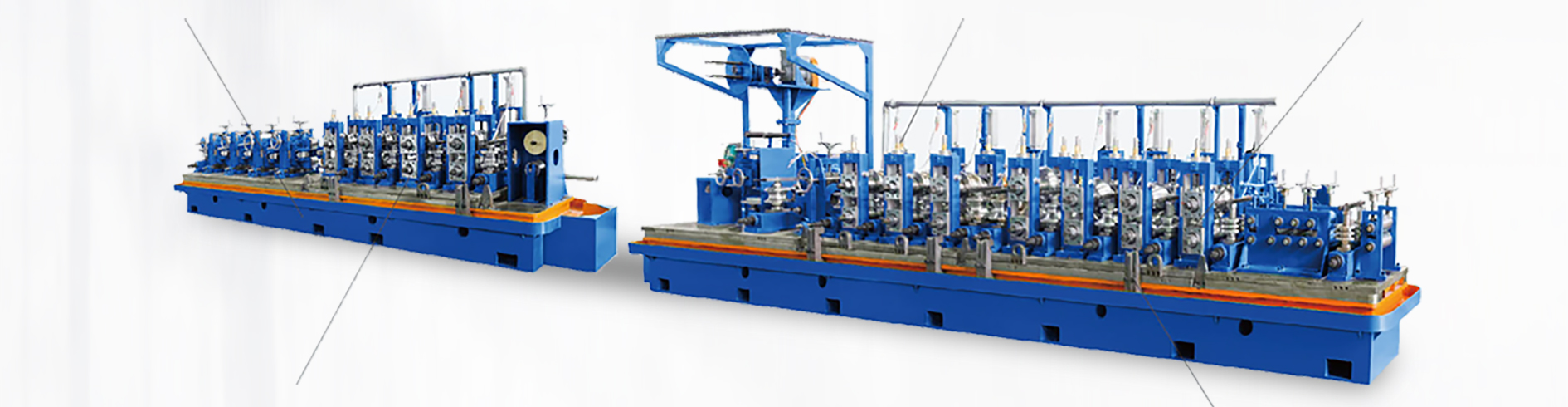

I-ERW Steel Tube Mill Line

BuzaI-ERW Steel Tube & Pipe Mill Line

- Inzuzo -

Isisekelo somshini esiqinile futhi esingakhubazekile

Sebenzisa insimbi ewugqinsi ukushisela ndawonye iyonke ukuze ushise amahora angaphezu kwama-4 kabili ukuze uqiniseke ukuthi umshini ungasetshenziswa isikhathi eside ngaphandle kokuguqulwa.

Ukuvikela isikulufu

Ukusebenzisa i-bronze ukulungisa nut ukuvikela isikulufu, donsa ukushaqeka njengesici saso sokuzilungisa.

Impilo ende yokuzala

Ifakwe ama-nozzles okugcoba okugcoba okuthwala, impilo yokuzala ithuthukiswa kakhulu.

Ukuma okusheshayo

I-AlI okhiye bokumisa kanye nezimbobo zamabholithi zicutshungulwa yimishini ye-CNC, ngokunemba okuphezulu.

Uhlelo oluhlakaniphile

I-Roller eku-inthanethi ne-othomathikhi

Uhlelo Lokushintsha Okusheshayo

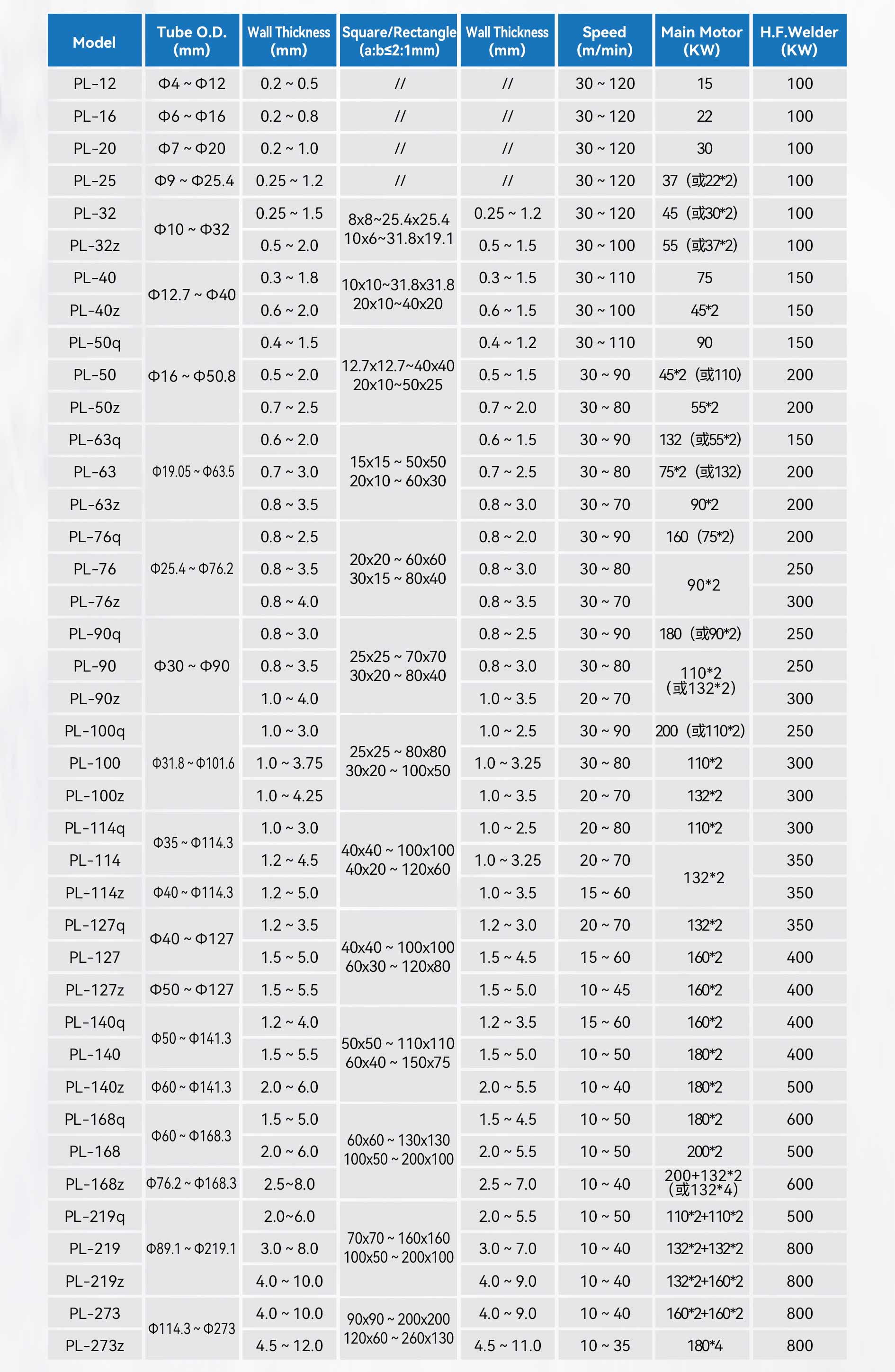

- Ipharamitha yezobuchwepheshe -

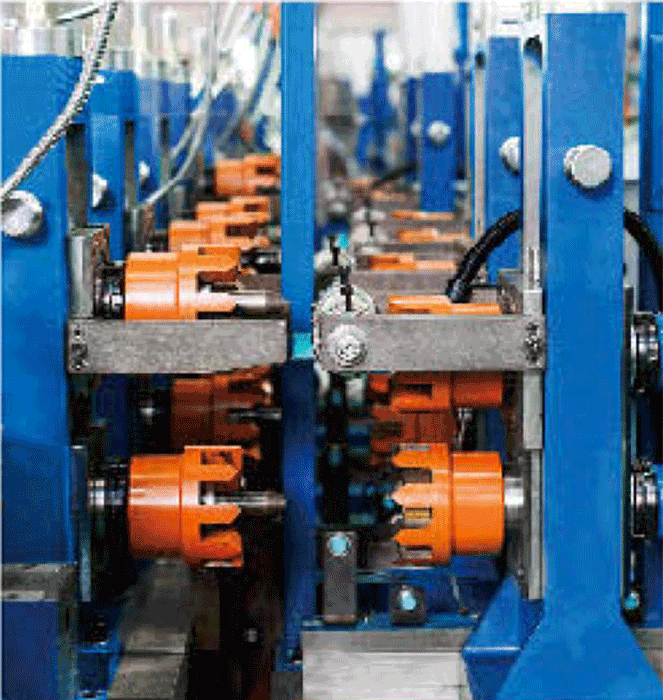

I-Roller Quick Change System

10 imiz

Shintsha i-roller emaminithini angu-10

30 imiz

Qalisa kabusha ukukhiqiza emizuzwini engama-30

Uma ushintsha usayizi wepayipi uye kwelinye, i-rniddle ima ne-universal coupling systern iya emuva futhi ikhulule ngokuzenzakalelayo kusuka kumashafu avundlile aphezulu naphansi, Iqhutshwa injini noma isistimu ye-hydraulic.

Emishinini emincane nemaphakathi yamamodeli, phakamisa inkundla yonke ngezitendi ezivundlile nezime mpo namarola kude nesisekelo somshini, bese uphakamisa enye inkundla efanayo nerola yepayipi edingekayo efakwe ngaphandle komugqa kusisekelo somshini, izitendi ezimaphakathi ezinohlelo lokuhlanganisa lomhlaba wonke ziye phambili futhi zihlanganise ngokuzenzakalelayo amashafti avundlile aphezulu naphansi, aqhutshwa injini noma isistimu ye-hydraulic.

Emishinini emincane nemaphakathi yamamodeli, phakamisa inkundla yonke ngezitendi ezivundlile nezime mpo namarola kude nesisekelo somshini, bese uphakamisa enye inkundla efanayo nerola yepayipi edingekayo efakwe ngaphandle komugqa kusisekelo somshini, izitendi ezimaphakathi ezinohlelo lokuhlanganisa lomhlaba wonke ziye phambili futhi zihlanganise ngokuzenzakalelayo amashafti avundlile aphezulu naphansi, aqhutshwa injini noma isistimu ye-hydraulic.